No products in the cart.

The prefinished, sculpted tongue and groove lining system.

The prefinished AND preassembled acoustic linear batten system.

Award winning Group 1 perforated wall covering for high acoustic comfort.

Explore our comprehensive range and find the perfect finish for your project.

Modulo® Group 1 tongue and groove board lining is an innovative extension to Screenwood’s bestselling Modulo® MR range.

Specially designed for the highest fire-rated interior environments, it presents a new, cost-effective, pre-finished solution for those seeking creative freedom to sculpt dynamic woodgrain interiors.

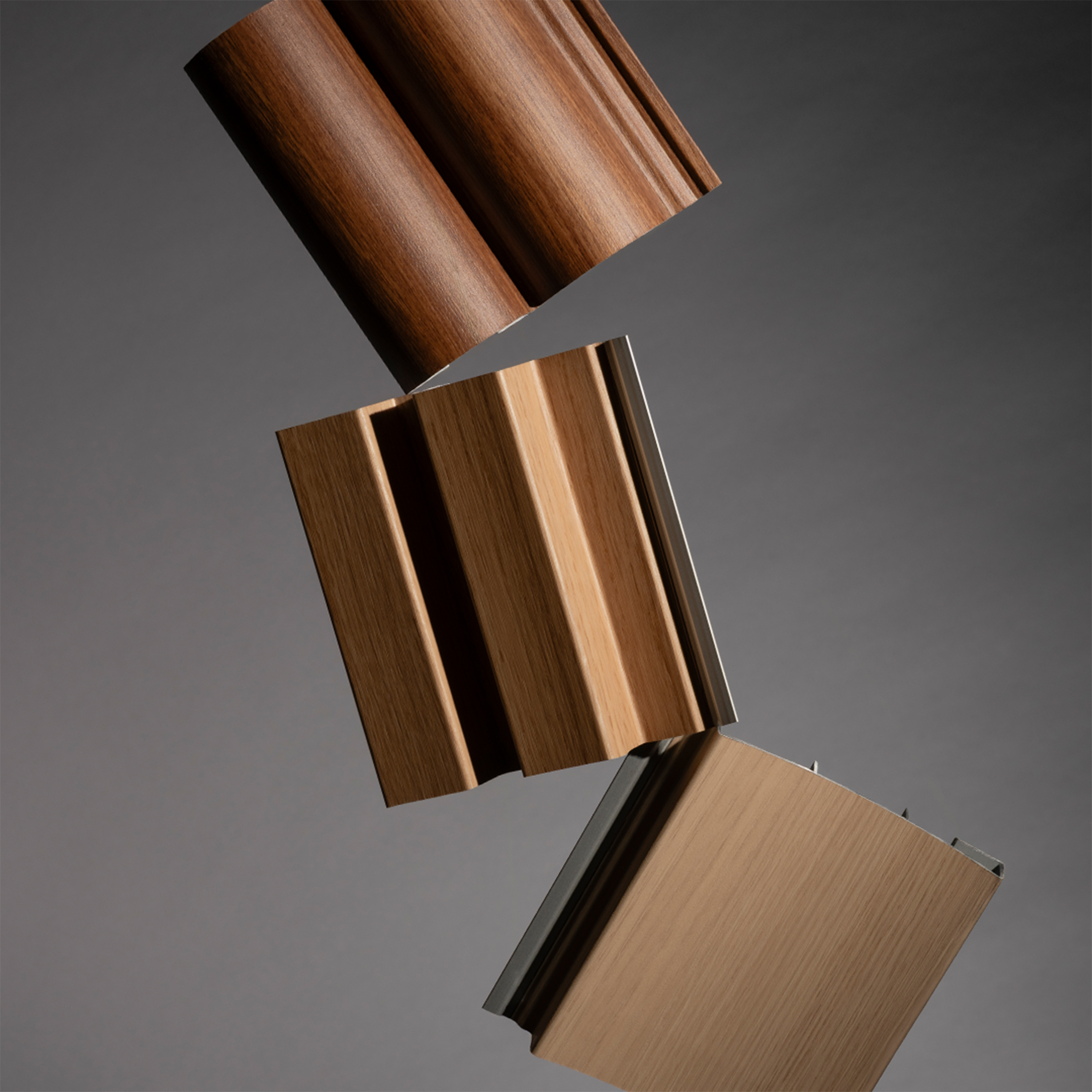

3 Profiles designed for creative exploration

Modulo® Group 1 features an advanced and compliant technical design for 3 profiles – Batten, Arc and Flute, each with key features:

Modulo® Group 1 tongue and groove boards are specifically designed for interior environments requiring a Group 1 fire rating.

Watch: The difference between Modulo® Group 1 and Modulo® MR.

Watch: The difference between Modulo® Group 1 and Modulo® MR.

Modulo® Group 1 Aluminium is available pre-finished in a choice of over 30 premium NAVURBAN™ decorative surfaces.

NAVURBAN™ Range – Silken, Elements, and ultra-realistic woodgrain empowers the exploration of contemporary biophilic design trends using more natural-looking 3D textured or embossed woodgrain finishes instead of typical powder-on-powder painting.

High Quality and Durable Finish

Easy Cleaning and Maintenance

Easy and Cost-Effective Installation

Modulo® Group 1 is crafted using hollow, lightweight aluminium. It is easier to cut, carry, and curve, ensuring a faster and more cost-effective installation – no prep work required.

Ideal Interior Environments

Modulo® Group 1 is a superb choice for interior environments where strength, durability, and fire safety are paramount.

This includes hotels, clubs, retail, hospitality, education, corporate, aged care, healthcare and multi-res developments.

Certified and Tested To Perform Under The Toughest Conditions

*Pending

Australian Designed and Made

Screenwood is proud to manufacture Modulo® in Australia, supporting our local jobs and economy. Its meticulous craftsmanship and end-to-end manufacturing control ensure the highest attention to detail and quality standards.

Customers can explore more information about Modulo® Group 1 and order high-quality samples here.

Alternatively, contact our team at hello@screenwood.com.au or call us on +61 2 9521 7200.

Related links

Share article

In the spirit of reconciliation, Screenwood acknowledge the Traditional Custodians of Country throughout Australia and their connections to land, sea, and community. We pay our respects to their Elders past, present, and emerging, and extend that respect to all Aboriginal and Torres Strait Islander peoples today.

Screenwood is committed to ethical business practices and has implemented comprehensive measures to identify, prevent, and address modern slavery risks within our operations and supply chains in accordance with the Australian Modern Slavery Act 2018.

Our products are for everyone, and so is our workplace. We believe in constantly building a diverse and inclusive culture for a more equitable world.

Subscribe and be the first to hear about our new products, case studies, and industry insights.

Terms & Conditions | Privacy Policy | © 2025 Screenwood Pty Ltd